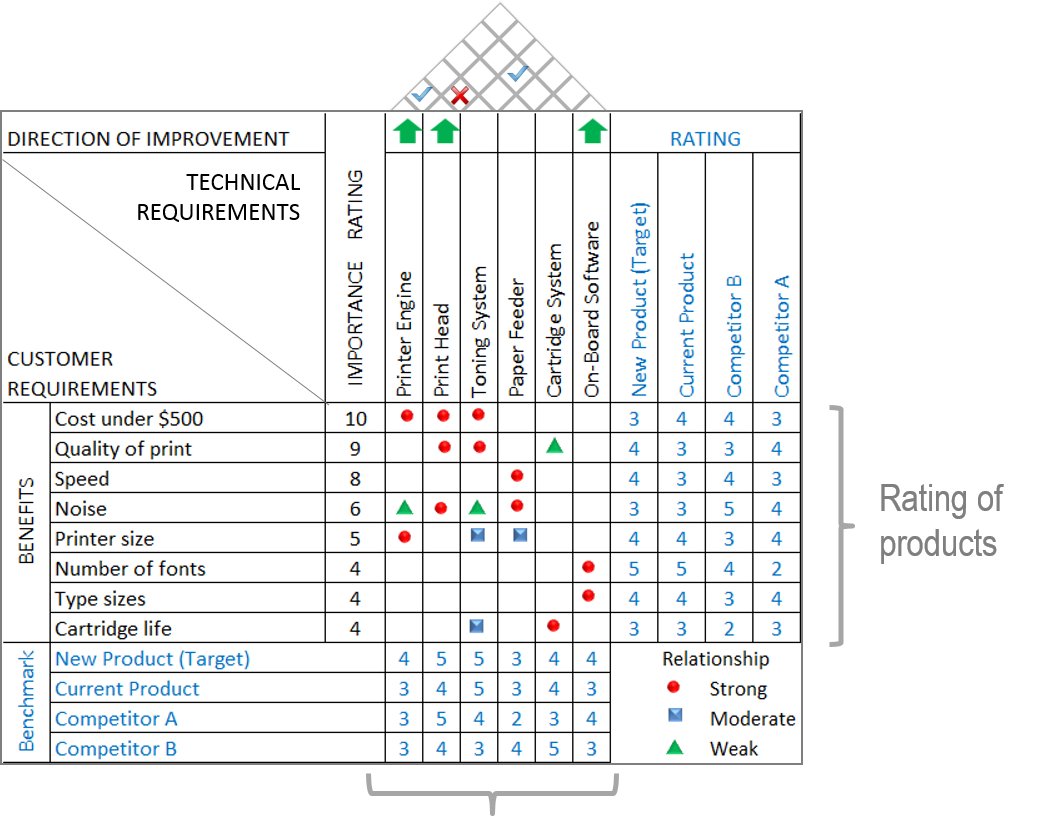

Exhibit 10.9 Simplified version of the house of quality for

laser printers.

The “house of quality” originated at

Mitsubishi Kobe shipyard in 1972, as a tool for translating customer

requirements into engineering and manufacturing parameters that are measurable

and controllable. Over the years its use has spread to a number of sectors

including automotive, IT, consumer durables, apparel, and a wide range of B2B

products and services.

House of quality is a conceptual framework that

provides the means for cross-functional planning and communication, so that

marketing, R&D and manufacturing may work together to produce products that

reflect the preferences of customers.

Exhibit 10.9 depicts a much-simplified version of

the house of quality for laser printers. In a typical application there would

be about 15 to 50 consumer requirements and 30 to 100 technical requirements.

The building blocks for the house of quality are as

follows:

- List of customer requirements (product attributes).

- Importance ratings of these attributes: This may be obtained from

product tests where preference ratings by customers are modelled to determine

the importance of each attribute. Alternatively conjoint analysis provides

the means for determining the importance of attributes and their specific level

in terms of part-worth.

- Customer rating of performance on consumer attributes of new

product and competing products. This too may be sourced from product tests or

conjoint analysis.

- List of engineering characteristics.

- Relationship between customer attributes and engineering

characteristics: Whereas the customer requirements spell out customers’

preferences, the engineering requirements tell us how the product may be

modified. A product’s performance on a customer attribute is often affected by

multiple design parameters. For instance, the noise level of a laser printer is

affected by print head technology, centrifugal fan and paper feeder. The

relationship matrix indicates the extent to which each product characteristic

affects each customer attribute. These ratings are usually based on the

judgement of experienced engineering and marketing associates.

- Relationship within engineering characteristics. The roof matrix

specifies whether a change in one characteristic affects another. For instance,

improvements in the cartridge system will result in improvements in the toning

system.

- Benchmarks: Objective measures of performance on engineering

characteristics for the new product and competing products.

- Judgments of technical difficulties, imputed importance and costs

of achieving target engineering characteristics (Not shown in Exhibit 10.9).

The house of quality is essentially an elegant approach to

depicting comprehensive product design information within a single construct,

in a manner that associates from different disciplines can readily comprehend.

It improves cross-functional planning and communication, and leads to quicker,

superior decisions.